While everyone here at the shop has some kind of personal experience with air suspension, we know not everyone does. So when someone comes in and asks us questions, we treat them well and answer every one they ask. We want you to be more informed on the subject. After all, we love welcoming people into the air bagged community.

But if you don’t have the ability to come into the shop or give us a call — or you’re maybe too shy to ask — don’t worry. We’re going to run down the basics on the topic and give you an idea of what air suspension is exactly, and how it works.

It Starts with Air

You have probably driven or ridden in a vehicle with air suspension before. Some luxury cars have it standard and have for decades, as have buses, ambulances, and firetrucks. While those kinds of cars don’t use air to lay their ride on the ground, they are a testament to the reliability of air suspension for everyday use.

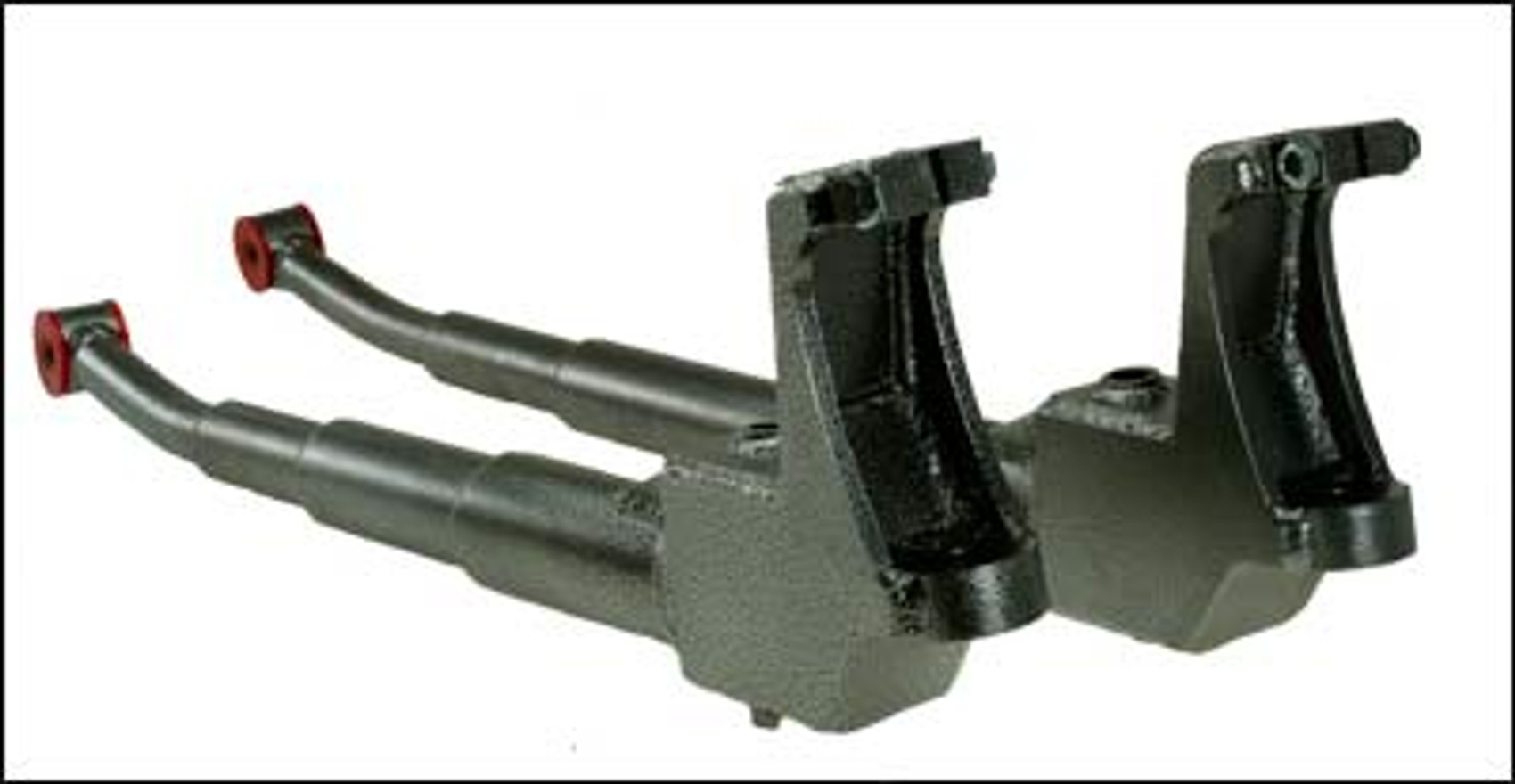

Air suspension starts with an air bag of some kind. There are vehicle-specific air bags and universal models, but the idea is basically the same. This air bag replaces or provides extra support to the spring on your vehicle, and gives you a way to adjust the ride height of the suspension.

A coil spring supports the weight of your car or truck, and so if the air bag replaces the coil spring, it has to do the same task. This means you need an air bag that can handle the weight of your vehicle.

If you are keeping the spring — like in the rear of a truck and a leaf spring — then an air bag can provide additional carrying capacity. This is where an air bag helper kit comes into play, which allows you to tow more weight or carry more payload in your truck.

Air Comes From Compressors and Goes to Tanks

The air to fill the air bags has to come from somewhere, and in this case the air is created by an air compressor. The air compressor does what you think it does — it compresses the air — and pushes it into a storage unit of some kind. This is typically an air tank, and they come in various capacities.

There is a balance that you need to build between the air compressor and the air tank. If the tank is too large, the air compressor may take too long to fill it up, which means you might need another compressor. If the tank is too small, then you won’t be able to fill up your airbags without the compressors kicking in, which then means it takes longer for you to lift up to drive.

Air Moves with Valves, Through Air Lines

To direct the air to the appropriate place, you need to install air valves or an air manifold, which is made of individual air valves like this one. Both serve the same purpose: you trigger a valve using a switch and then the valve opens, directing air to or from the appropriate air bag. You can get air valves that are manual or electric.

The air moves from the valves to their destination through air lines. These come in various diameters, and you can get either Department of Transportation (D.O.T.) versions, or a metal hard line that requires specialized tools to install. Air line has to be secured to the vehicle and away from any moving parts that could cause them to wear.

If there is a connection between any two components, it will likely need a fitting of some sort. These allow the two parts to mate properly, and have to be installed with thread sealant to prevent air leaks.

It’s a Lot, But It’s Awesome.

Air suspension does require a lot of parts, but fortunately, we have kits premade for certain vehicles or setups. And again, if you have any questions, don’t hesitate to reach out and ask. That’s what we’re here for.